ABB Autonomous Mobile Robots (AMR): logistics 4.0

In the dynamic context of modern logistics, ABB's Autonomous Mobile Robots (AMRs) are emerging as key players in the 4.0 transformation. These AMRs, operating without drivers, ensure uninterrupted operations, 24 hours a day, 7 days a week. They are shaping the future of efficient goods flows, and revolutionizing management practices in transport and warehousing operations. Among the cutting-edge technologies guiding these AMRs, the SLAM (Simultaneous Localization and Mapping) method is positioned as the central engine of their autonomous, intelligent navigation.

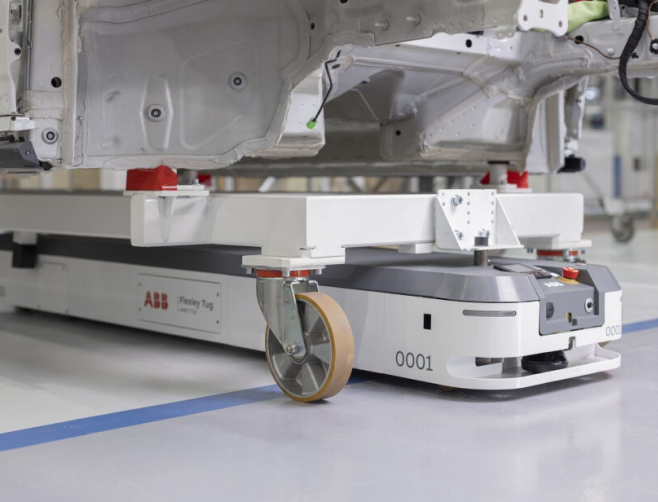

Robot AMR - "Flexey Tug" tractors

With compact dimensions, generous capacity and exceptional maneuverability, our "Flexey Tug" series of Autonomous Mobile Robots (AMRs) presents a robust, easy, safe and adaptable solution for moving carts. Subject to rigorous performance and safety validations, these robots are operational 24/7, positioning themselves as tireless partners for intralogistics towing applications.

The advantages of AMR "Flexley Tug" tractors

Thanks to its user-friendly interfaces and proven performance, our range of AMRs offers ease of use that guarantees optimum performance, generating high productivity and reduced operational costs in your intralogistics operations. Our Flexley Tug robots provide a solution that's easy to install, operate and maintain.

NOur new 2.0 evolution also incorporates SLAM navigation technologies, faster loading systems and increased load capacity.

The ideal solution for towing in logistics and manufacturing flows. With its high load capacity and compact dimensions, our unbeatable range of Flexley Tug vehicles can be adapted to a wide variety of wheeled carts and containers.

AMR Robots - "Flexley Mover" carriers

Featuring excellent maneuverability thanks to its compact design and omnidirectional technology with in-place rotation. Our Flexley Mover AMRs are equipped with the latest navigation systems and technologies, offering increased agility and efficiency for moving your goods in intralogistics.

Why choose Flexley Mover robots

This innovative range of robots is designed to meet your business needs in terms of operational flexibility, responsiveness, peak demand management, productivity and safety, as well as for the delivery of carriers, pallets, containers, boxes or hanging garments in confined spaces and narrow aisles.

Thanks to intelligent navigation technology, combined with advanced software intelligence, this range of ABB AMR robots can perform operations from multiple origin points to multiple destinations to meet the high demands of your logistics processes.

Our Flexley Mover range can transport carriers with all kinds of product combinations, containers of different sizes and pallets of all types - from Euro pallets to American pallets and special-size pallets.