Mol road-rail tractor vehicles

The power and dependability of Mol road-rail tractor vehicles

Mol is a manufacturer of special vehicles with world wide reach. The company is more than 70 years old and designs vehicles capable of working in even the harshest environments. Great attention is paid to the choice of high quality components which is what makes Mol vehicles such outstandingly reliable working tools.

Based on its know-how, Mol has developed a range of road-rail vehicles with towing capacities ranging from 16 to 40 tonnes. Fitted with power plants ranging from 160 kW to 380 KW to the EURO5 standards, these road-rail vehicles can pull trainsets weighing anything from 1800 to 4500 tonnes.

With the capability of running on roads or rails, the road-rail vehicles are intended for use in applications demanding intensive railway carriage towing solutions. Road-rail vehicles are as suitable for driving on the road as on rails, allowing fast transfers between sites. Operating in places where goods wagons need to be moved locally at low speed (< 25 km/h) is one of the requirements facing companies with private marshalling yards, ports, cement and chemical industry, steelworks and terminals.

Versatile

Requiring 9 metres in the 4 steered wheels version and 15 metres in the 2-wheel version to get on or off the track, MOL's road-rail vehicles have guide bogies at the front and at the rear. Track changes are made by road. This ability of road-rail vehicles to get about by road reduces the costs of maintaining multiple tracks and simplifies the road-rail network on your site.

Depending on the model, road-rail vehicles can operate on tracks with rail gauges ranging from 1067 mm to 1676 mm. Note that the standard rail gauge in France is 1435 mm.

It takes less than two minutes to mount the vehicle on the track and less than 30 seconds to remove it. With its two cameras and the monitor screen in the cab, the operator can monitor accurately the position of the road-rail vehicle in relation to the tracks.

A state-of-the-art PLC assists the operator in the track-mounting and exit operations. In particular, it controls the conversion of the lighting and signalling devices when the vehicle is running alternately on the track or on the road.

Maximum grip and guidance

Rubber tyres provide traction on the rails. Road-rail vehicles develop higher driving and braking forces than a locomotive because of the friction coefficient of rubber on steel.

The road-rail vehicle is driven by means of permanent four-wheel drive. The differentials of the driving axles are locked when used on tracks. An anti-skid system ensures that the driving force is optimised when the train starts and limits tyre wear.

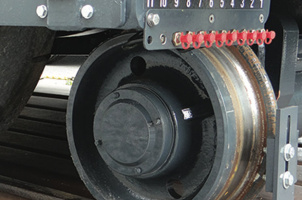

The vehicle is accurately steered by means of the steering axles equipped with single or double bogie rail wheels (diameter 400 mm). Each steering axle is kept under constant pressure by hydropneumatic suspension controlled by the automatic assistance system.

Large volume accumulators make for a smoothly responsive hydropneumatic suspension. The pressures on the rail guide wheels are constantly monitored and automatically adjusted if necessary.

Manoeuvrability

A selector switch changes the direction of the road-rail vehicle while the vehicle is moving. There are 3 steering modes:

- 2 steering (front) wheels

- 4-wheel steering - optional

- Crab ride - optional

2 wheels (front) steerable

4 wheel steering

Crab ride

Systèmes de freinage

Les rails-routes sont équipés de deux systèmes de freinage, le frein véhicule (le frein direct) et le frein ferroviaire complet (le frein indirect). Les freins véhicules sont des freins à air comprimé à double circuit. Le frein d’urgence et le frein de stationnement garantissent l’immobilisation du véhicule, même s’il n’y a pas de pression d’air (failsafe).

Le frein ferroviaire commande également les freins du véhicule rail-route lors de son utilisation sur les voies ferrées.

Une vanne d’arrêt d’urgence ouvre le circuit général en cas d’urgence.

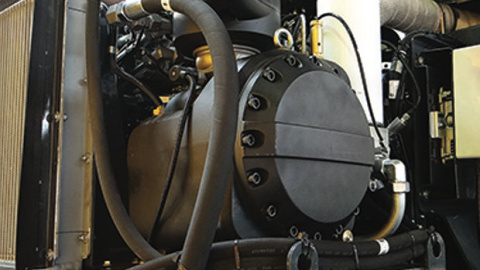

Les deux systèmes de freinage disposent chacun de leur compresseur et de leur réservoir d’air :

- Un compresseur est monté sur le moteur diesel et génère l’énergie pour les freins véhicules

- Un compresseur à vis entraîné (pas sur RR1644 & RR2044) avec un débit d’environ 3.600 l/min à 10 bar, et un grand réservoir d’air capacité de 800 L remplissent les freins des wagons très rapidement.

Safety

Safety was the key element in the choice of technical solutions during the development of the road-rail vehicle.

Numerous safety features prevent malfunctions, breakdowns, operating errors or carelessness, thereby protecting the equipment from damage and helping to avoid accidents:

- Steps with lighting and handles that comply with railway regulations

- Handrails all around the vehicle

- Wide and secure steps at each end of the vehicle. Passage at the front and rear of the vehicle

- Dead man's device

- Optical and acoustic signalling for road and rail operations

- Emergency stop buttons at every corner of the vehicle

- Constant monitoring and automatic correction of the pressure on the guide system

- Low centre of gravity of the vehicle

- Robust frame, high crash resistance

- Safety control of mode changes: "road mode", "rail mode" and "remote rail mode".

- Air conditioning system

- Radio remote control

- Exhaust gas purification systems

- Spark arrestors

- 4 steered wheels

- Automatic couplings and/or special couplings

- Swivelling driver's seat with dual controls

- Derailment detectors

- Automatic lubrication system

And many more.

Les locotracteurs rail-route MOL sont construits selon les règles reconnues et répondent aux normes EN15746

Conçus avec des experts reconnus par l’Autorité des chemins de fer fédérale allemande (EBA), les rails-routes MOL sont conformes aux normes ferroviaires de la certification §32 EBO, répondant aux exigences de sécurité de la Deutsche Bahn AG.

Cette certification a servi de base pour obtenir les certifications ferroviaires en Belgique, France, Allemagne, Suisse, Autriche, Hongrie, Slovénie, etc.