Smarter technology for more efficiency at the right time

Konecranes is a pioneer in the field of reach stacker technology. Konecranes has launched the world's first hybrid reach stacker. All Konecranes reach stackers are equipped with powerful, low-emission engines. They comply with environmental standards and regulations and have low fuel consumption levels.

Aprolis offers a complete range of accessories and services to meet handling requirements in the industrial sector (concrete, steel, etc.), container logistics in seaports and inland ports, multimodal platforms, rail freight.

Efficient and versatile handling of containers and goods

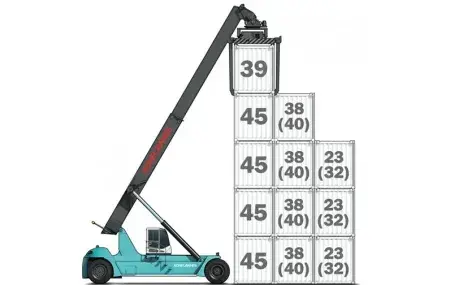

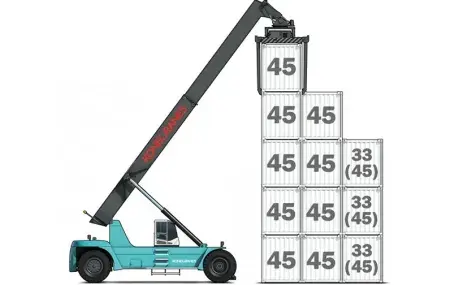

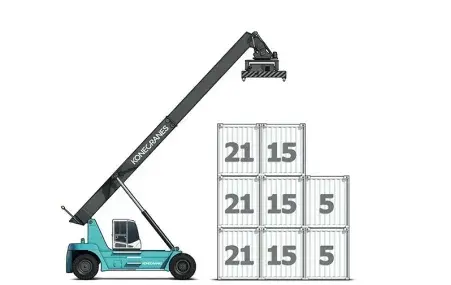

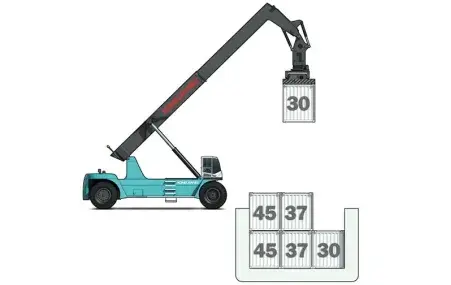

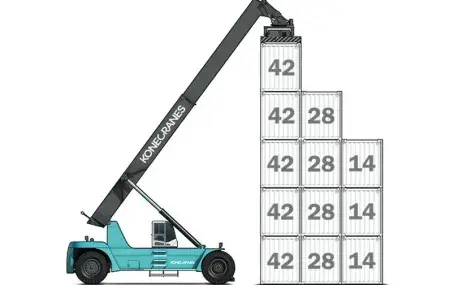

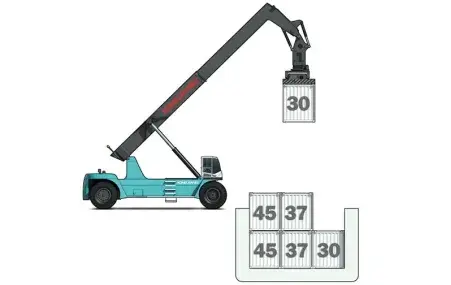

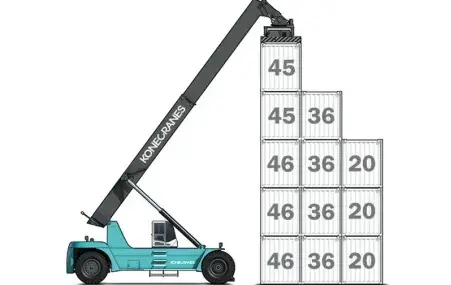

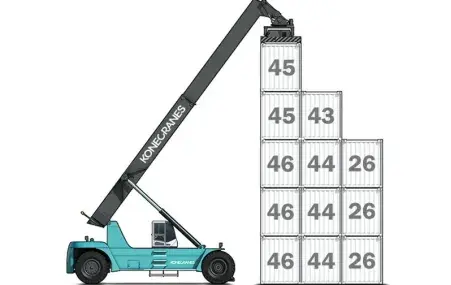

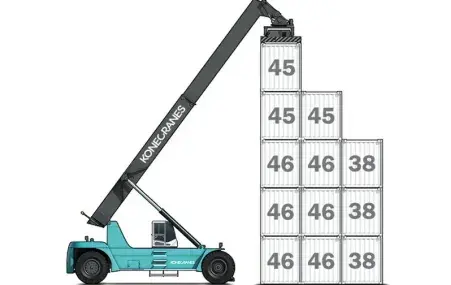

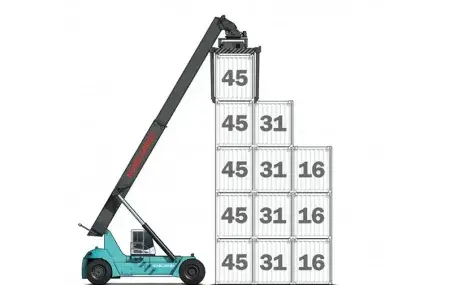

The Konecranes Reach Stacker range, with capacities ranging from 33 to 80 tonnes, has both proven technologies and innovative, eco-efficient functions to increase productivity and reduce costs throughout the life of your equipment.

See the range

The curved glass provides operators with an exceptional field of view.

The very wide glass panes without corner posts, the slim but particularly strong roof rail and the curved panels offer an unrivalled experience in terms of ergonomics, visibility and safety.

The OPTIMA cab is one of the most spacious cabs on the market.

Its design is clearly focused on the operator.

Total ergonomics: all the controls are within the operator's reach.

The hydraulic system senses the weight of the load and adjusts the lifting power accordingly.

The engine speed is always proportional to the load being handled.

As a result, these reach stackers offer better fuel economy, produce fewer emissions and have a low noise level.

You can control vital components and functions through a 7" (approx. 17 cm) touch screen.

CanBus technology enhances the reliability of not only the engine and transmission, but also of the hydraulic system and joystick.

Flow Drive Technology

Based on 2nd generation HVT technology, Flow Drive comes with software developed by Konecranes Lift Trucks, as well as the engine reconfiguration function.

The result is a quieter cab, smoother driving and easier direction changes, contributing to the overall well-being of the operator and helping to make him more productive.

Flow drive reduces fuel consumption and emissions by up to 25%.