Crown counterbalanced stacker – power and flexibility for your logistics operations

Crown counterbalanced stackers combine the manoeuvrability of a compact stacker with the stability of a traditional forklift. Available in various capacities (up to 1,800 kg), they are designed to ease stacking, transport and storage, including in high-density logistics environments.

Why choose a Crown counterbalanced stacker?

Industrial and logistics companies face often tight spaces, varied loads and sustained rhythms. Crown counterbalanced stackers meet these challenges thanks to:

- A compact and robust design: ideal for narrow aisles and congested areas.

- Versatile use: loading/unloading, high storage, handling of non-standard loads.

- Operator-focused ergonomics: intuitive controls, power steering and excellent visibility for confident operation.

Crown stacker models

In-frame arm stacker – SH Series

Designed for daily loading, unloading and stacking operations, the SH series stacker stands out for its reliability and ease of use.

- Rated capacity: up to 1,800 kg

- Max lift height: 4,875 mm

Fork spacing: 863 to 1,271 mm

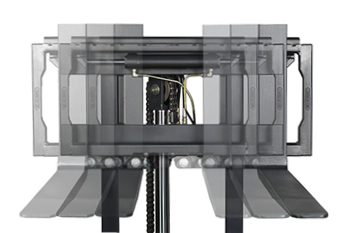

Pantograph stacker – SHR Series

The SHR stacker features a pantograph system, allowing forks to extend to handle pallets of different sizes, with tilt possible forwards or backwards.

- Rated capacity: 1,100 to 1,600 kg

- Max lift height: 4,875 mm

Fork spacing: 863 to 1,271 mm

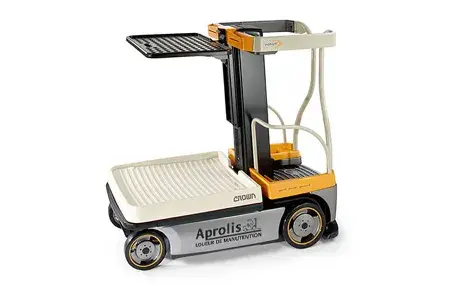

Counterbalanced stacker – SHC Series

A real alternative to a counterbalanced forklift, the SHC combines counterweight stability with stacker compactness. It excels at loading docks and demanding storage areas.

- Rated capacity: 1,100 to 1,800 kg

- Max lift height: 4,365 mm

Overall width: 940 to 990 mm

Performance and safety at the heart of the design

Crown counterbalanced stackers incorporate innovative technologies to ensure smooth and safe operations:

- Access 1 2 3® technology: intelligent performance management and real-time diagnostics.

- Powerful AC traction system: for fast travel, even with heavy loads.

- Ramp-holding and speed control: enhanced safety on slopes and docks.

- X10® ergonomic tiller: simplified controls, reduced operator fatigue.

Robustness and durability for maximum productivity

Each Crown stacker is built to withstand the most demanding environments:

- Reinforced thick steel chassis.

- Industrial mast to support loads at height.

- Cast aluminum tiller with reinforcing core.

- Steel engine covers to protect internal components.

Options and accessories for a custom stacker

Fast charging, maintenance-free, with flexibility for partial charging.

For precise pallet repositioning.

Adapted for each application.

No need to remove the battery.

Ensured performance even in refrigerated environments.

Better pallet stability at height.

Crown Counterbalance Stackers

What is a counterbalance stacker?

It is a handling device that combines the compactness of a stacker with the stability of a front-loading forklift, thanks to an integrated counterweight system.

What is the difference between a straddle stacker and a counterbalance stacker?

A straddle stacker uses outriggers to stabilize the load, while a counterbalance stacker (SHC series) does not require them, allowing the handling of closed or special pallets.

What is the maximum load capacity of a Crown counterbalance stacker?

Depending on the model, the rated capacity ranges from 1,100 to 1,800 kg.

Can a counterbalance stacker be used in a confined space?

Yes, their compact design and maneuverability technologies make them perfectly suited for narrow aisles and crowded docks.

What are the advantages of lithium-ion batteries on a counterbalance stacker?

They provide very short charging times, allow opportunity charging, and require no maintenance.