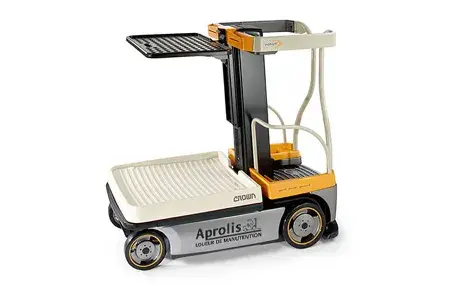

High-Level Order Picker Crown SP: Performance and Safety in Warehouses

The high-level order pickers of the Crown SP series offer a unique combination of visibility, stability, and speed. Designed for demanding logistics environments and very narrow aisles, they allow operators to work efficiently up to over 10 meters in height while handling loads of up to 1000 or 1250 kg depending on the model.

High-Level Order Picker Crown SP Models

High-Level Order Picker with Fixed Forks Crown SP1510

Ideal for picking heavy or bulky products, the fixed forks model of the SP series combines robustness and ergonomics. It is perfectly suited for wider platforms and rolls, and can be used in free or guided aisles.

- Rated capacity: 1250 kg

- Maximum fork lift height: 10,210 mm

- Platform maximum lift height: 10,380 mm

High-Level Order Picker with Auxiliary Lift Crown SP1520

Designed to reduce operator effort, the auxiliary lift model allows load height adjustment and optimizes working postures. Suitable for free and guided operations, it ensures comfort and safety even in very narrow aisles.

- Rated capacity: 1000 kg

- Maximum fork lift height: 9,650 mm

Platform maximum lift height: 9,005 mm

360° Visibility for Increased Safety

Visibility is a key factor for high-level performance. Thanks to intelligent design, Crown SP order pickers provide the operator with a clear view of their environment:

- Panoramic windows integrated into the mast and overhead guard

- Floor openings to see the area under the platform

- Clear forward/backward views for smooth high-level maneuvers

Result: better anticipation of obstacles and a significant reduction of risks in the warehouse.

High-Level Performance for Modern Logistics

Crown SP high-level order pickers incorporate innovative solutions to boost productivity:

- Optimized lift and lower speeds

- Xpress Lower technology: twice as fast lowering

- Enhanced stability at height thanks to the OnTrac system

- Spacious and ergonomic operator compartment

Every detail is designed to streamline operations and reduce cycle times.

Operator-Centered Design

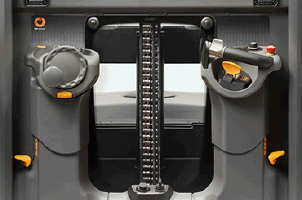

Operator comfort is essential to maintain warehouse performance. The SP series includes:

- Optional dual controls for greater flexibility

- Compartment adaptable to different body sizes

- Height-adjustable control modules

Large workspace to facilitate movement

Prioritizing Intelligent Safety to Build Confidence

High-level order picking is physically demanding and requires both concentration and vigilance. Crown SP high-level order pickers integrate intelligent systems that support the operator in real-time, enhance safety, and improve productivity. With their four stable points of contact and advanced digital solutions, they create a safer, ergonomic, and reassuring work environment.

Gena Operating System: Intuitive and Connected Experience

The Gena system provides the operator with a 7-inch touchscreen interface, programmable in over 40 languages. The customizable tiles display the most relevant performance indicators for the operator (truck status, energy consumption, lifting data…). Result: intuitive navigation and better real-time understanding of truck performance.

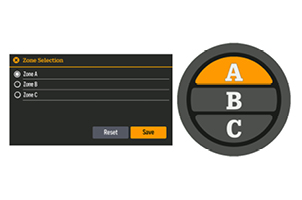

Zone Selection for Warehouse Safety

The “Zone Selection” function allows defining up to three safe lift height zones, depending on warehouse constraints. Directly accessible via the touchscreen, it helps the operator adapt movements and limit high-level risks by easily selecting the active zone.

Infolink: Fleet Management and Operator Safety

Available as an option, the Crown Infolink system combines access control, daily checklists, impact detection, and real-time alerts. It can also automatically lock the equipment in case of a safety issue. By analyzing operational and historical data, Infolink identifies risk zones and highlights opportunities to improve safety and overall productivity.

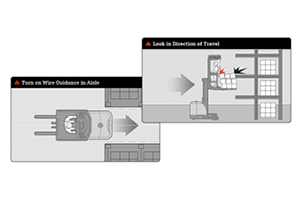

Digital Coaching and Integrated Safety Messages

Once logged in, the operator receives safety reminder messages on the truck display. The interactive display provides contextual help, automated coaching, and alerts tailored to the situation. These reminders promote vigilance, reduce maneuvering errors, and reinforce operator confidence in daily tasks.

Lithium-Ion Batteries: More Autonomy, Less Hassle

Available with lithium-ion batteries, the SP series offers decisive advantages over lead-acid batteries:

- Fast and safe partial charging

- Extended autonomy without battery change

- Low maintenance and reduced operating costs

Enhanced safety and zero emissions

Maximum Durability and Availability

Built to last, Crown SP order pickers stand out for their robustness and ease of maintenance:

- Reinforced steel chassis

- Separated electronic and hydraulic systems

- Wireless software updates

- Easy access for preventive maintenance

Many options allow each Crown SP picker to be tailored to your operations:

Crown SP High-Level Order Picker

What is a high-level order picker?

It is a specialized forklift that allows picking items stored at height (up to over 10 m), safely, with the operator in an elevated cabin.

What is the maximum capacity of Crown SP pickers?

Depending on the model, the rated capacity is 1000 kg (auxiliary lift) or 1250 kg (fixed forks).

In what type of warehouse should a high-level picker be used?

They are particularly suited for very narrow aisles, high-density storage areas, and platforms requiring high productivity.

What are the differences between lead-acid and lithium-ion batteries?

Lithium-ion batteries provide greater autonomy, fast partial charging, longer life, and require much less maintenance.

Which accessories improve safety and productivity?

Key options include automatic guidance, pedestrian detection system, LED fans and lights, and Work Assist accessories.